The manufacturing process of the faucet mainly includes:

Faucet Design – Mould Production – Sand Core Making Process – Melting the tested copper material – Gravity Casting – CNC Machining – Polishing – Surface Treatment – Strict Inspection and Assembly

There are corresponding inspections at each stage of the entire production process to ensure the quality of the faucet, including raw material analysis, salt spray testing, 100% airtightness testing…

Please follow our lens to see the production process of the Martube faucet manufacturer

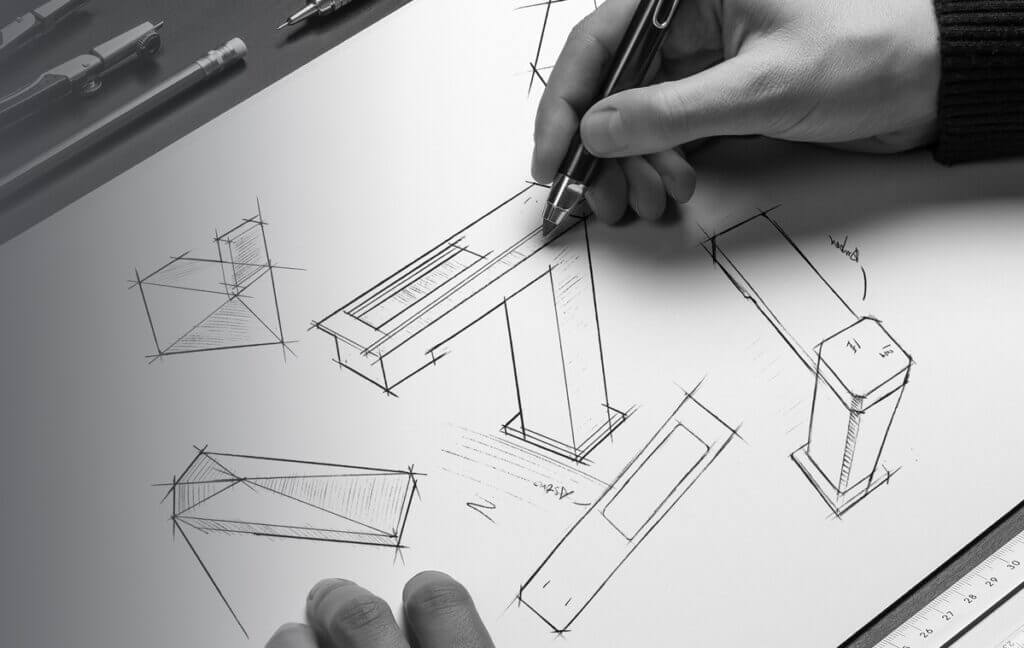

Faucet Design

Martube faucet manufacturer has its own design team dedicated to continuous innovation and research. Use rich design knowledge and innovative creation experience to meet customer needs.

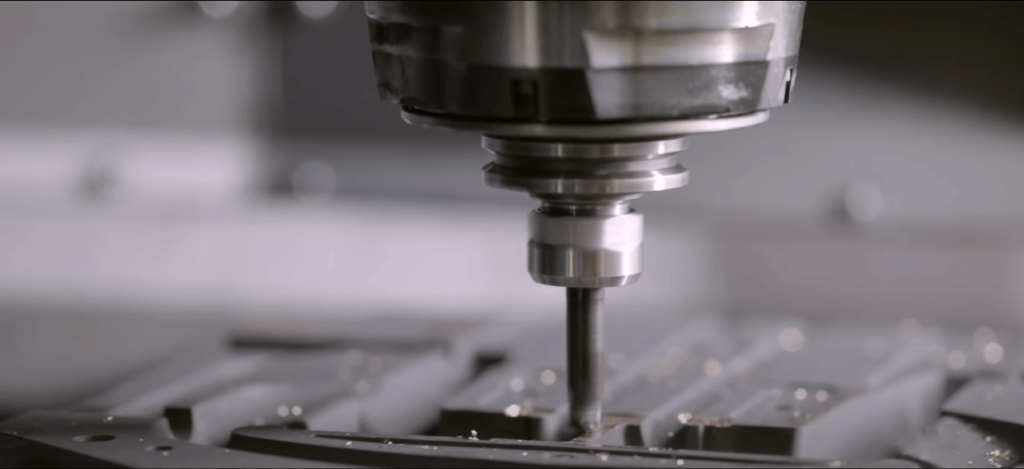

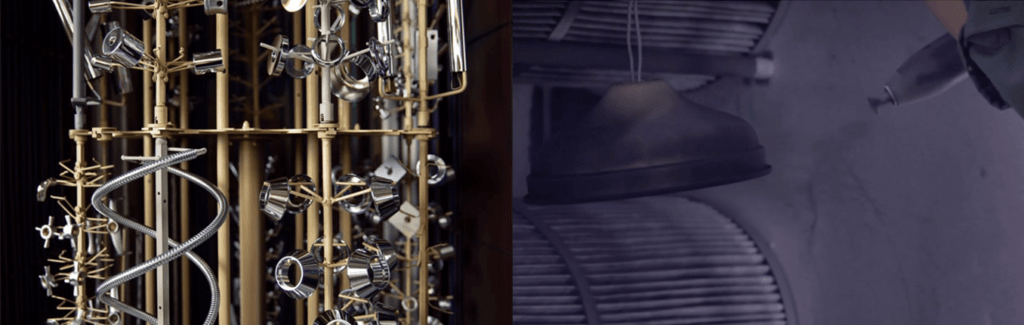

Mould Production

The mold is the fixture for the faucet forming. Only the mold that is carefully designed and processed by the precision CNC machine tool can make a high-quality faucet. Workbench for mold development.

Sand Core Making Process

The sand core creates water channels inside the faucet.

Raw Material

The influence of copper on the quality of faucets: high-quality raw materials are an indispensable component of high-quality faucets. Martube’s faucets are made of brass above H58, due to its good corrosion resistance and sterilization function.

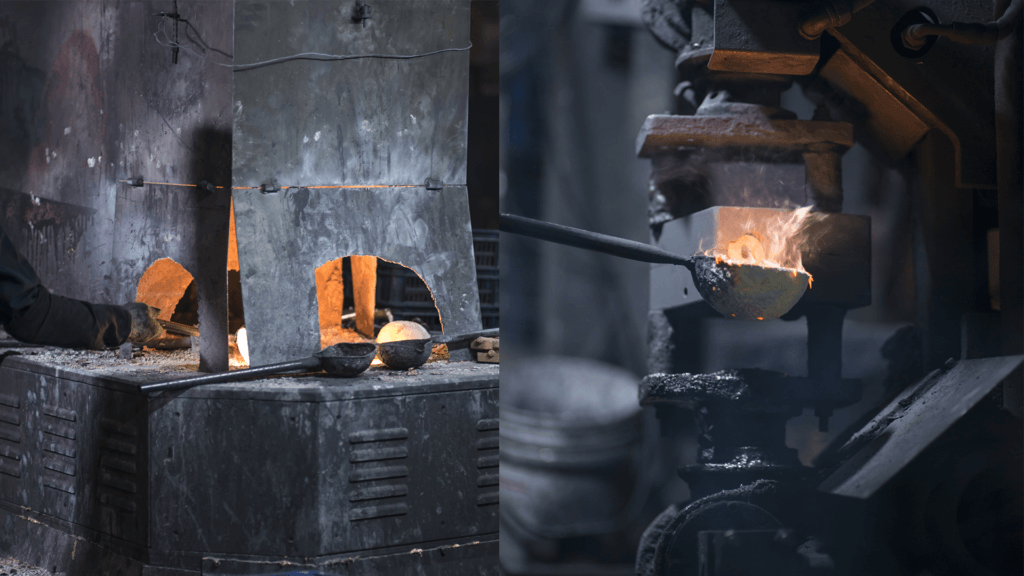

Gravity Casting

Fix the prepared mold and sand core in a gravity die-casting machine, melt high-quality brass ingots in a high-temperature furnace, inject liquid copper into the mold, and let the brass flow through the entire mold by gravity. After a short period of cooling, the main body of the faucet is formed.

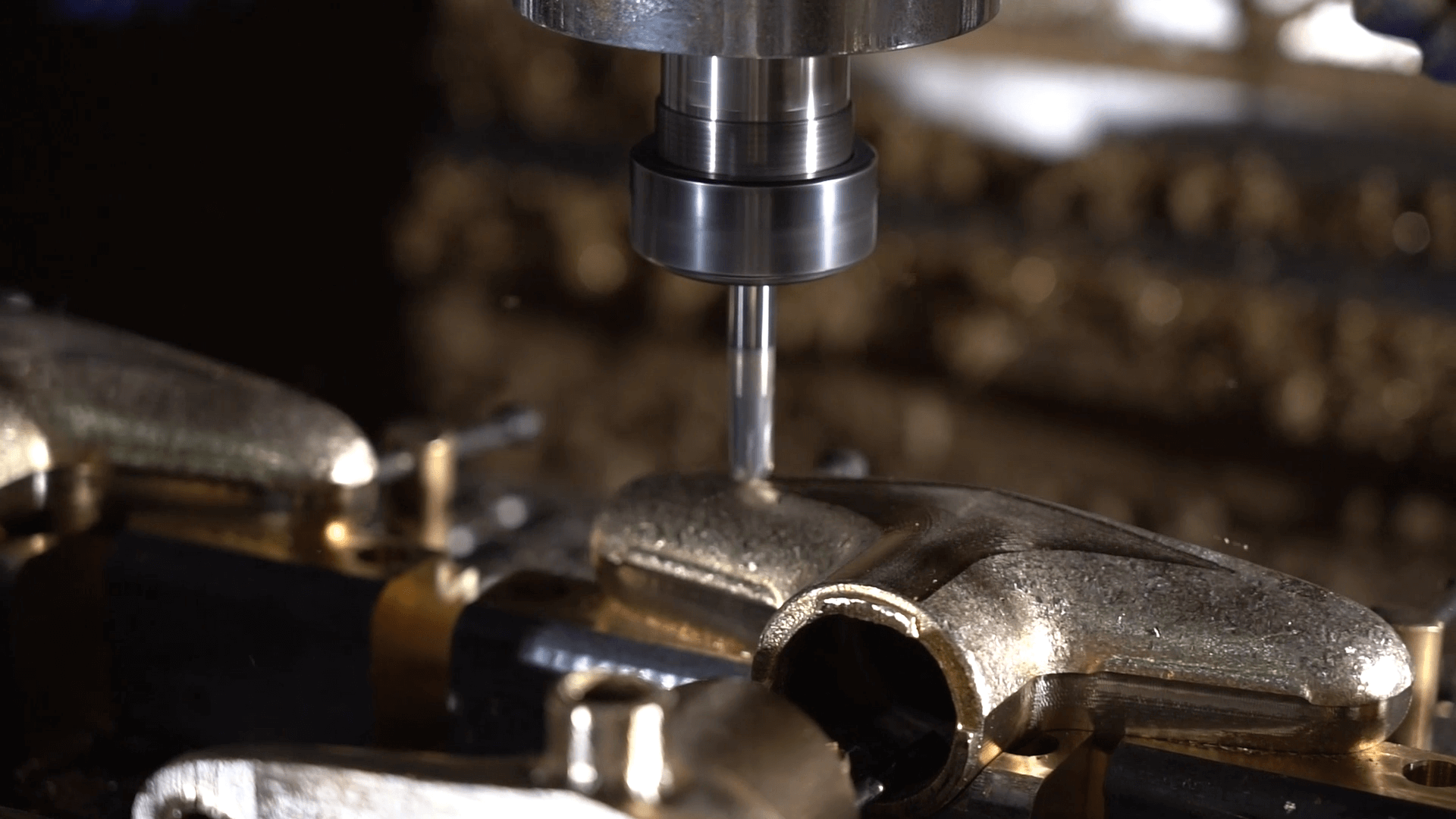

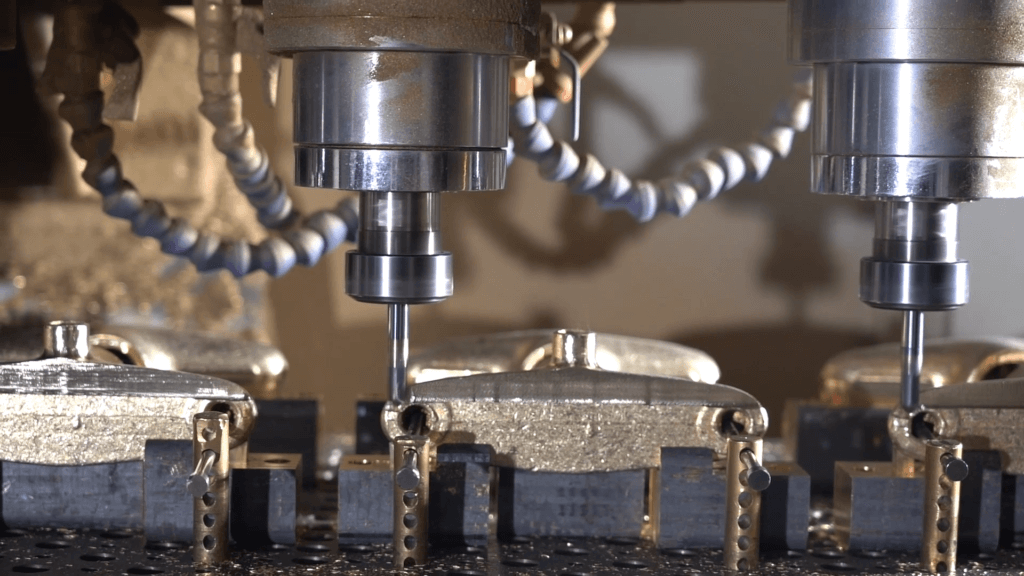

CNC Machining

CNC machining machines perform various cutting operations on the main body, such as turning, drilling, thread cutting and thread cutting. Reach the required dimensional accuracy and meet the drawing requirements.

Polishing

Polishing makes the surface of the faucet more flat

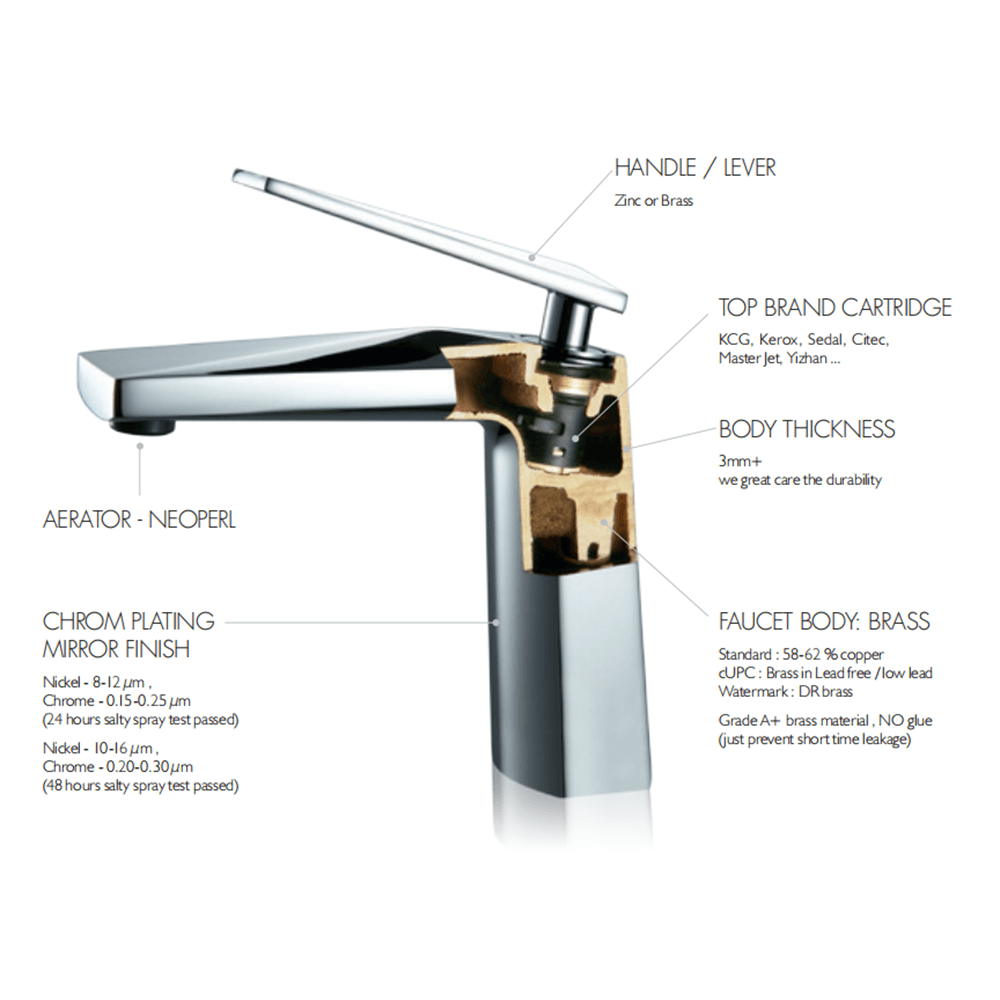

Surface Treatment

Martube’s faucets have a premium quality finish that will stand the test of time. is one of our biggest differences

The surfaces of Martube faucets are divided into Electroplate, PVD, Painting, Coating Finishes. The most durable are Electroplate and PVD two processes. Nickel and chrome plating protects the surface from corrosion and imparts an aesthetically pleasing appearance. In addition, PVD and Painting process diversify the faucet colors

Strict Inspection and Assembly

Important accessories such as Cartridge, Aerators and Inlet Flexible Hose are also an important part of affecting the quality of the faucet. Martube all use faucet accessories from well-known brands, such as

Sedal Cartridge, KCG Cartridge, Neoperl Aerators, etc.

Finally, Martube’s QC will check each part of the faucet components, the workshop staff will assemble the whole faucet, after the tightness test, the faucet will be packaged and ready to be delivered to the customer